Agrobacterium-mediated Transformation of Embryogenic Cell Suspensions: A Complete Protocol for High-Efficiency Genetic Engineering

This comprehensive guide details the optimized protocol for Agrobacterium-mediated transformation of embryogenic cell suspensions (ECS), a cornerstone technique for advanced plant genetic engineering and molecular pharming.

Agrobacterium-mediated Transformation of Embryogenic Cell Suspensions: A Complete Protocol for High-Efficiency Genetic Engineering

Abstract

This comprehensive guide details the optimized protocol for Agrobacterium-mediated transformation of embryogenic cell suspensions (ECS), a cornerstone technique for advanced plant genetic engineering and molecular pharming. Covering foundational principles, step-by-step methodology, critical troubleshooting, and rigorous validation strategies, this article provides researchers and biopharmaceutical developers with the essential knowledge to efficiently produce recombinant proteins, secondary metabolites, and genetically modified plants. We explore recent advancements in vector design, co-cultivation conditions, and selection regimes to maximize transformation efficiency and transgenic recovery, directly supporting applications in drug development and sustainable biomedicine.

Understanding the Engine: Principles of Agrobacterium and Embryogenic Cultures

Application Notes

Agrobacterium tumefaciens is a soil-borne pathogen and the causative agent of crown gall disease. Its unique ability to transfer a segment of its tumor-inducing (Ti) plasmid DNA, the T-DNA, into the genome of host plant cells has been harnessed as the premier method for plant genetic engineering. This natural genetic engineering process is central to the broader thesis on optimizing Agrobacterium-mediated transformation of embryogenic cell suspensions for crop improvement and synthetic biology applications.

The virulence (vir) region of the Ti plasmid encodes the molecular machinery for T-DNA processing, transfer, and integration. Key steps include: perception of plant-derived phenolic signals (e.g., acetosyringone) by the VirA/VirG two-component system; activation of vir gene expression; excision of the single-stranded T-DNA (ssT-DNA) by VirD1/VirD2 endonucleases; and ssT-DNA translocation into the plant cell via a Type IV Secretion System (T4SS). Within the plant cell, the T-DNA complex is escorted to the nucleus by VirD2 and VirE2, where it integrates into the host genome.

Recent advances (2023-2024) highlight the use of engineered Agrobacterium strains (e.g., EHA105, LBA4404 derivatives) with superbinary vectors containing additional vir genes (virG, virE) to enhance transformation efficiency in recalcitrant species, including monocots. Furthermore, the development of "transformation booster" molecules like cysteine and lipo-chitooligosaccharides has improved T-DNA delivery and cell survival in embryogenic suspensions.

Table 1: Key Quantitative Metrics in Modern Agrobacterium-mediated Transformation (2020-2024)

| Metric | Typical Range (Model Plants) | Typical Range (Recalcitrant Crops/Embryogenic Suspensions) | Key Influencing Factor |

|---|---|---|---|

| Transformation Efficiency (% of treated cells) | 70-90% (Arabidopsis leaf discs) | 1-30% (Monocot embryogenic calli) | Strain/Virulence Helper, Acetosyringone concentration |

| Optimal Acetosyringone Concentration | 100-200 µM | 200-400 µM | Plant species, explant type |

| Co-cultivation Duration | 2-3 days | 3-5 days | Temperature (19-22°C optimal) |

| Optimal Co-cultivation Temperature | 19-22°C | 20-22°C | Avoids overgrowth, enhances T-DNA transfer |

| T-DNA Copy Number Integration (Average) | 1.5 - 2.5 | 1.2 - 5.0 | Strain, vector design, selection pressure |

Table 2: Comparison of Common Agrobacterium Strains for Embryogenic Suspension Transformation

| Strain | Ti Plasmid Backbone | Key Features for Embryogenic Suspensions | Best For |

|---|---|---|---|

| EHA105 | pTiBo542 (supervirulent) | High vir gene activity, excellent for monocots | Rice, maize, wheat suspensions |

| LBA4404 | pAL4404 (disarmed) | Low background, stable, requires superbinary vector | Dicots, some monocots with vir helpers |

| AGL1 | pTiBo542 | Contains modified virE locus, high transformation | Arabidopsis, tobacco, potato |

| GV3101 | pTiC58 | RIF^R, GENT^R, good for floral dip, some suspensions | Nicotiana species, some dicot suspensions |

Experimental Protocols

Protocol 2.1: Preparation of Embryogenic Cell Suspensions for Agrobacterium Co-cultivation

Objective: To establish and maintain friable, embryogenic callus tissue suitable for efficient T-DNA transfer. Materials:

- Embryogenic callus from mature seeds or immature embryos.

- Suspension Initiation Medium (SIM): MS basal salts, 2 mg/L 2,4-D, 30 g/L sucrose, 0.5 g/L proline, pH 5.8.

- 125 mL Erlenmeyer flasks.

- Orbital shaker (110-130 rpm).

Procedure:

- Transfer ~2 g of friable embryogenic callus into a 125 mL flask containing 25 mL of liquid SIM.

- Seal with breathable closure. Incubate in darkness at 25±2°C on an orbital shaker set to 110-130 rpm.

- Subculture every 7 days by allowing cells to settle, removing ⅔ of the spent medium, and replacing with fresh SIM.

- After 3-4 subcultures, a fine, homogeneous suspension of small cell aggregates (approx. 50-200 cells) should form. Use this for transformation 3-4 days after the last subculture.

Protocol 2.2: Agrobacterium-mediated Transformation of Embryogenic Cell Suspensions

Objective: To deliver T-DNA from Agrobacterium into embryogenic plant cells. Materials:

- Actively growing embryogenic suspension (Protocol 2.1).

- Agrobacterium strain (e.g., EHA105) harboring the binary vector of interest.

- Induction Medium (IM): MS salts, 2 mg/L 2,4-D, 100-200 µM acetosyringone, 10 g/L glucose, pH 5.2.

- Co-cultivation Medium (CCM): Solidified SIM with 100-200 µM acetosyringone.

- Washing Medium: Liquid SIM with 500 mg/L carbenicillin or cefotaxime.

Procedure:

- Agrobacterium Preparation: Grow Agrobacterium overnight in LB with appropriate antibiotics. Pellet cells and resuspend in IM to an OD600 of 0.5-1.0. Induce for 2-4 hours at 28°C with gentle shaking.

- Co-cultivation: Mix 1 mL of induced Agrobacterium suspension with 1 mL of settled plant cells in a 2 mL microtube. Incubate for 15-30 minutes with gentle inversion.

- Transfer the mixture onto sterile filter paper placed on CCM plates. Seal plates and co-cultivate in darkness at 21°C for 3 days.

- Washing: Transfer the filter paper with cells to a sterile container. Gently wash cells with 50 mL Washing Medium, agitating to remove excess Agrobacterium. Repeat wash 2-3 times.

- Resuspend washed cells in fresh SIM with antibiotics (carbenicillin/cefotaxime) and plate onto Selection Medium containing appropriate selective agent (e.g., hygromycin, kanamycin).

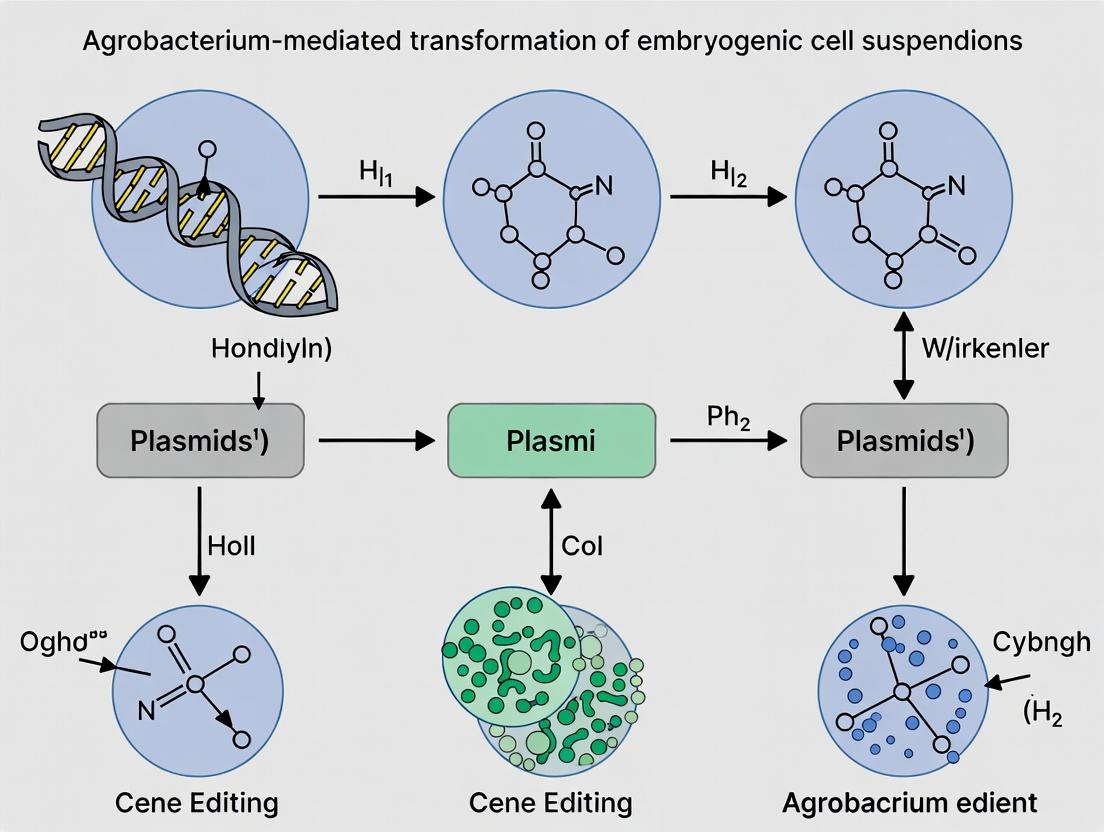

Visualizations

T-DNA Transfer Signal Transduction Pathway

Embryogenic Suspension Transformation Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Agrobacterium-mediated Transformation of Embryogenic Suspensions

| Item | Function & Rationale |

|---|---|

| Acetosyringone | A phenolic compound that activates the Agrobacterium VirA/VirG two-component system, inducing vir gene expression. Critical for efficient T-DNA transfer, especially in monocots. |

| 2,4-Dichlorophenoxyacetic acid (2,4-D) | Auxin analog used in culture media to induce and maintain the embryogenic, dedifferentiated state of plant cells, making them competent for transformation. |

| Carbenicillin / Cefotaxime | β-lactam antibiotics used to eliminate Agrobacterium after co-cultivation. They are preferred over penicillin due to stability in plant culture media and low phytotoxicity. |

| Selection Agent (e.g., Hygromycin B, Kanamycin) | Antibiotic or herbicide corresponding to the resistance gene on the T-DNA. Allows selective growth of transformed plant cells that have integrated the T-DNA. |

| Superbinary Vector (e.g., pSB1) | A binary vector containing additional virB, virG, or virE genes from a super-virulent Ti plasmid. Dramatically increases T-DNA transfer efficiency into recalcitrant plant species. |

| Lipo-chitooligosaccharides (LCOs) | Signaling molecules that can act as "transformation enhancers" by modulating plant defense responses and promoting cell survival during the transformation process. |

| Silwet L-77 | A non-ionic surfactant. When used at low concentrations in co-cultivation media, it improves Agrobacterium attachment and T-DNA delivery to plant cells by reducing surface tension. |

This Application Note is framed within a thesis research program focused on advancing Agrobacterium-mediated transformation for high-value crop and pharmaceutical compound production. Embryogenic Cell Suspensions (ECSs) represent a critical starting material, offering unique advantages over traditional explants like leaf discs or callus clumps. Their primary utility lies in enabling high-throughput genetic transformation and synchronized regeneration of transgenic plants, which is essential for scaling functional genomics, metabolic engineering, and the production of plant-made pharmaceuticals.

The following table consolidates key performance metrics of ECSs versus solid callus explants, as established in recent literature.

Table 1: Comparative Performance of ECS vs. Solid Callus Explants in Transformation

| Parameter | Embryogenic Cell Suspension (ECS) | Solid Callus Explants | Reference/Model System |

|---|---|---|---|

| Transformation Efficiency | 40-75% (stably transformed lines) | 10-30% | Rice, Maize, Citrus |

| Time to Regenerate Plantlets | 12-16 weeks post-transformation | 20-28 weeks | Conifer species, Oil Palm |

| Scale Potential (explants/experiment) | High (10⁵-10⁶ cells/flask) | Limited (50-200 pieces/plate) | Tobacco BY-2, Arabidopsis cell cultures |

| Synchrony of Development | High (Homogeneous cell population) | Low (Heterogeneous tissue pieces) | Somatic Embryogenesis systems |

| Chimerism in Regenerants | <5% | 15-40% | Various dicot and monocot crops |

| Suitability for Automation | Excellent (Liquid handling robotics) | Poor (Manual transfer required) | High-throughput screening platforms |

Detailed Protocols

Protocol 1: Initiation and Maintenance of Embryogenic Cell Suspensions

- Objective: To establish a fine, rapidly dividing, and homogenous suspension culture from embryogenic callus.

- Materials: See Scientist's Toolkit.

- Method:

- Select 1-2g of friable, embryogenic callus (4-6 weeks old) and transfer to a 125ml Erlenmeyer flask containing 25ml of liquid maintenance medium (e.g., MS or N6 basal salts with reduced ammonium, 2,4-D, and sucrose).

- Place flask on an orbital shaker at 100-120 rpm in the dark at 25±2°C.

- Subculture every 7 days by allowing cells to settle for 10 minutes, decanting 2/3 of the spent medium, and resuspending the settled cells in fresh pre-warmed medium. The ideal inoculum density is 1-2ml packed cell volume per 25ml fresh medium.

- After 4-5 subcultures, sieve the suspension through a 500µm stainless steel or nylon mesh to remove large aggregates. The fine suspension passing through is the established ECS.

Protocol 2: High-ThroughputAgrobacterium-Mediated Transformation of ECS

- Objective: To genetically transform ECS cells at high efficiency using Agrobacterium tumefaciens.

- Materials: See Scientist's Toolkit.

- Method:

- Preculture: Subculture ECS 3 days prior to transformation to ensure actively dividing cells.

- Bacterium Preparation: Grow Agrobacterium strain (e.g., EHA105, LBA4404) harboring the binary vector in LB with appropriate antibiotics to an OD₆₀₀ of 0.5-0.8. Pellet bacteria and resuspend in liquid co-cultivation medium (CCM) to an OD₆₀₀ of 0.1.

- Co-cultivation: Mix 2ml of settled ECS cells with 10ml of the Agrobacterium suspension in a Petri dish. Incubate in the dark at 22-25°C for 48-72 hours with gentle agitation.

- Washing & Selection: Transfer the co-cultivated cells to a sterile 50ml tube and wash 3-5 times with sterile CCM containing 500mg/L cefotaxime or carbenicillin to eliminate Agrobacterium.

- Plating: Resuspend the washed cells in 10ml of selection medium (CCM with appropriate antibiotic/herbicide for plant selection and bacterial suppressant). Plate thinly over solid selection medium in large (150 x 25 mm) Petri dishes.

- Culture: Maintain plates in the dark at 25°C. Subculture proliferating, putatively transformed embryogenic clusters to fresh selection plates every 14 days.

Protocol 3: Regeneration of Transgenic Plants from Transformed ECS

- Objective: To regenerate whole, transgenic plants from selected embryogenic clusters.

- Method:

- After 2-3 selection cycles, transfer vigorously growing, antibiotic-resistant embryogenic clusters (1-2mm diameter) to regeneration medium lacking auxin (2,4-D) and containing a cytokinin (e.g., BAP).

- Incubate under a 16/8-hour photoperiod with cool white fluorescent light (50-100 µmol m⁻² s⁻¹).

- Within 2-4 weeks, somatic embryos will develop and germinate into plantlets.

- Once plantlets develop true leaves and a root system, carefully transfer them to soil or a sterile potting mix in a containment greenhouse. Acclimatize by covering with a clear dome to maintain high humidity for the first week.

Visualizations

Title: High-Throughput Transformation & Regeneration Workflow

Title: Key Signaling in Somatic Embryogenesis

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents for ECS Transformation

| Reagent/Material | Function & Rationale | Example/Typical Concentration |

|---|---|---|

| 2,4-Dichlorophenoxyacetic acid (2,4-D) | Synthetic auxin; induces and maintains embryogenic competence in cells. | 0.5 - 2.0 mg/L in maintenance medium |

| Acetosyringone | Phenolic compound; induces Agrobacterium vir genes during co-cultivation, enhancing T-DNA transfer. | 100 - 200 µM in co-cultivation medium |

| Cefotaxime / Carbenicillin | Beta-lactam antibiotics; eliminate Agrobacterium after co-cultivation without phytotoxic effects. | 250 - 500 mg/L in wash/selection media |

| Selection Agent (e.g., Hygromycin, Kanamycin, Glufosinate) | Selective pressure; allows growth of only transformed cells expressing the resistance gene. | Concentration is species-specific (e.g., 50 mg/L Hygromycin for rice) |

| Gelling Agent (Gelzan, Phytagel) | Provides solid support for selection and regeneration; clearer than agar, low interference. | 2.5 - 3.0 g/L |

| L-Cysteine & Dithiothreitol (DTT) | Anti-browning agents; reduce phenolic oxidation and cell death in sensitive species post-co-cultivation. | 100-400 mg/L (Cysteine), 10-50 mg/L (DTT) |

| Enzymes (Pectinase, Cellulase) | Used for generating Protoplasts from ECS for direct DNA uptake or more uniform transformation. | 0.5-1.0% solution for cell wall digestion |

1. Introduction

Within the framework of Agrobacterium-mediated transformation of Embryogenic Cell Suspensions (ECS) for plant biotechnology and molecular pharming, the design of the transformation vector is paramount. Success hinges on the precise selection of binary vector components and selectable marker genes tailored to the unique, sensitive physiology of embryogenic cells. This document outlines the core genetic elements, provides quantitative comparisons, and details protocols for their effective use in ECS transformation.

2. Core Components of Binary Vectors for ECS

A standard T-DNA binary vector for ECS transformation must contain the following essential elements:

- Left Border (LB) and Right Border (RB): Flank the T-DNA; the RB is crucial for precise initiation of T-strand transfer.

- Selectable Marker Gene Expression Cassette: Drives selection of transformed cells. Must include a promoter active in ECS, the marker gene coding sequence, and a polyadenylation signal.

- Gene(s) of Interest (GOI) Expression Cassette: For therapeutic protein production, this typically includes a strong constitutive or inducible promoter, the GOI, and a terminator.

- Vector Backbone Sequences: Contains origins of replication for E. coli and Agrobacterium tumefaciens, and a bacterial selection marker.

Table 1: Quantitative Comparison of Common Promoters for Expression in ECS

| Promoter | Origin | Relative Strength in ECS* | Key Characteristic |

|---|---|---|---|

| CaMV 35S | Cauliflower Mosaic Virus | 100 (Reference) | Strong, constitutive, widely used in dicots. |

| ZmUbi | Maize (Zea mays) | 120-150 | Strong, constitutive, preferred for monocots; effective in many dicot ECS. |

| AtEF1α | Arabidopsis thaliana | 80-100 | Constitutive, often provides stable expression. |

| Rd29A | Arabidopsis thaliana | Low (Inducible: High) | Stress-inducible; minimal basal leakage, high induction. |

Relative strength is an approximate measure based on GUS or GFP reporter assays and varies by species.

3. Selectable Marker Genes for ECS Selection

Selection is critical as ECS are mixed populations. The marker must be lethal to non-transformed cells at an optimal concentration that does not over-stress the transformed tissue.

Table 2: Common Selectable Marker Genes for Plant ECS Transformation

| Marker Gene | Gene Product & Action | Typical Working Concentration (ECS) | Key Advantage for ECS |

|---|---|---|---|

| npII | Neomycin phosphotransferase II; detoxifies aminoglycosides (kanamycin, geneticin). | 50-100 mg/L Kanamycin | Well-characterized; reliable for many species. |

| hptII | Hygromycin phosphotransferase II; detoxifies hygromycin B. | 10-20 mg/L Hygromycin B | Very effective due to hygromycin's high toxicity to plant cells. |

| bar/pat | Phosphinothricin acetyltransferase; detoxifies glufosinate ammonium (BASTA). | 2-5 mg/L L-PPT (Glufosinate) | Effective chemical selection; also used for herbicide tolerance trait. |

| aadA | Aminoglycoside adenyltransferase; detoxifies spectinomycin/streptomycin. | 50-100 mg/L Spectinomycin | Useful for chloroplast transformation or as a second marker. |

Protocol 1: Determination of Optimal Selective Agent Concentration for a Novel ECS Line

Objective: To establish the minimum lethal concentration of a selective agent for untransformed ECS cells, ensuring efficient selection post-transformation.

Materials:

- Wild-type (non-transformed) ECS in log-phase growth.

- Liquid maintenance medium.

- Stock solution of selective agent (e.g., hygromycin B, kanamycin).

- Sterile 6-well culture plates.

Method:

- Prepare Dilution Series: Aliquot liquid maintenance medium into tubes. Add selective agent to create a series (e.g., 0, 5, 10, 15, 20, 25, 30 mg/L for hygromycin B).

- Plate Cells: Transfer 3-5 ml of each concentration to a well in a 6-well plate. Inoculate each well with a consistent volume (e.g., 200 µl) of settled ECS cells.

- Incubate and Monitor: Culture the plates under standard conditions (e.g., 25°C, dark, agitation). Observe weekly for 4-6 weeks.

- Score Viability: Record cell browning, cessation of proliferation, and loss of embryogenic morphology. The Minimum Lethal Concentration (MLC) is the lowest concentration that completely inhibits cell growth and causes 100% browning/death within 4 weeks.

- Validation: The optimal selection concentration for transformation experiments is typically 1.2x to 1.5x the determined MLC.

4. Visualizing T-DNA Transfer and Selection Workflow

Title: Workflow for ECS Transformation and Selection

5. The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagent Solutions for ECS Transformation Experiments

| Reagent / Material | Function & Rationale |

|---|---|

| Embryogenic Cell Suspensions (ECS) | Fast-dividing, totipotent target tissue ideal for transformation and regeneration. |

| Disarmed A. tumefaciens Strain (e.g., EHA105, LBA4404, GV3101) | Engineered for plant transformation; lacks oncogenes but retains T-DNA transfer machinery. |

| Binary Vector with T-DNA | Carries genes of interest and selectable marker for transfer into plant genome. |

| Acetosyringone Solution (100-200 µM) | Phenolic compound that induces the Agrobacterium Vir genes, enhancing T-DNA transfer efficiency. |

| Plant Culture Medium (Liquid & Solid) | Specifically formulated for the growth and maintenance of embryogenic cells (e.g., MS, B5 basal salts). |

| Selective Agent (e.g., Hygromycin B) | Eliminates non-transformed cells; critical for isolating transgenic events. |

| β-Glucuronidase (GUS) Assay Kit or GFP Microscope | For histochemical or visual confirmation of transient or stable transformation. |

| PCR Reagents & Primers | For molecular confirmation of transgene integration into the plant genome. |

Protocol 2: Agrobacterium-Mediated Transformation of Monocot ECS (e.g., Rice, Maize)

Objective: To stably transform embryogenic cell suspensions using Agrobacterium co-cultivation.

Materials:

- Log-phase ECS (7 days post-subculture).

- A. tumefaciens strain EHA105 harboring binary vector, grown overnight.

- Liquid co-cultivation medium (with 100 µM acetosyringone).

- Selection medium (solid, with appropriate antibiotic and 250-500 mg/L cefotaxime).

- Vacuum desiccator or centrifuge.

Method:

- ECS Preparation: Collect ECS by brief settling. Use ~2 ml packed cell volume (PCV).

- Agrobacterium Preparation: Pellet bacteria from 5 ml overnight culture. Resuspend in 10 ml liquid co-cultivation medium + acetosyringone to an OD600 of ~0.5.

- Infection: Combine ECS and Agrobacterium suspension in a sterile container. Apply a gentle vacuum infiltration (25-30 in Hg) for 5 minutes to enhance bacterial entry. Alternatively, incubate with gentle shaking for 30-60 minutes.

- Co-cultivation: Blot the ECS on sterile filter paper and transfer to solid co-cultivation medium + acetosyringone. Incubate in the dark at 22-25°C for 2-3 days.

- Selection: Transfer co-cultured ECS to solid selection medium. Subculture surviving, proliferating clusters to fresh selection medium every 2 weeks.

- Regeneration: After 2-3 selection cycles, transfer resistant, embryogenic clusters to regeneration medium to recover transgenic plants.

Within the broader thesis on optimizing Agrobacterium-mediated transformation (AMT) of embryogenic cell suspensions (ECS) for gene function studies and synthetic biology applications in drug development, three interdependent factors are critical for high-throughput, reproducible transgenic recovery. First, the host range of the Agrobacterium strain, dictated by its chromosomal background and virulence (vir) gene complement, determines its ability to transfer T-DNA to specific plant genotypes. Second, the precise induction of the bacterial virulence machinery via phenolic signals and optimal co-culture conditions is essential for efficient T-DNA transfer. Third, the embryogenic competence of the target plant cells—their inherent ability to regenerate via somatic embryogenesis—dictates the recovery of stable, transgenic plants post-transformation. Success hinges on synchronizing these factors, as high virulence induction in a broad-host-range strain is futile if the target cells lack robust embryogenic potential. These protocols detail methodologies to assay and optimize each factor for ECS systems.

Key Research Reagent Solutions

| Reagent / Material | Function in Experimental Context |

|---|---|

| Acetosyringone (AS) | Phenolic compound used to induce the expression of Agrobacterium vir genes during co-culture. Critical for maximizing T-DNA transfer efficiency. |

| L-Glutamine & Casein Hydrolysate | Organic nitrogen sources added to co-culture and recovery media to support embryogenic cell vitality and division post-Agrobacterium infection. |

| 2,4-Dichlorophenoxyacetic Acid (2,4-D) | Auxin analog used to maintain embryogenic cells in a proliferative, competent state within suspension cultures. |

| Timentin or Carbenicillin | β-lactam antibiotics used for post-co-culture elimination of Agrobacterium. Preferable to cefotaxime for some species due to lower toxicity to plant cells. |

| Modified MS or LM Medium | Basal culture media with optimized macronutrient and micronutrient ratios (often reduced NH4+) to support somatic embryogenesis in specific species (e.g., monocots). |

| GUS (β-glucuronidase) Reporter System | Histochemical or fluorometric assay to visualize transient T-DNA expression, serving as a rapid proxy for virulence induction and transformation efficiency. |

| Selective Agent (e.g., Hygromycin B) | Antibiotic or herbicide used in post-recovery regeneration media to select for transgenic events possessing the corresponding resistance gene on the T-DNA. |

Experimental Protocols

Protocol 3.1: Assessing Host Range Compatibility via Transient GUS Assay

Objective: To evaluate the efficiency of different Agrobacterium strains for T-DNA delivery into a novel embryogenic cell suspension (ECS) line. Materials: ECS (5 days post-subculture), Agrobacterium tumefaciens strains (e.g., EHA105, LBA4404, AGL1), AS, liquid co-culture medium, GUS staining solution, microscope. Procedure:

- Bacterial Preparation: Inoculate 5 mL of LB with appropriate antibiotics from a fresh colony of each Agrobacterium strain (harboring a binary vector with gusA). Grow overnight (28°C, 250 rpm).

- Induction: Pellet bacteria (5000 x g, 10 min). Resuspend in liquid co-culture medium (pH 5.2) containing 100-200 µM AS to an OD600 of 0.6-0.8. Induce for 2-4 hours at 28°C, gentle agitation.

- Co-culture: Mix 1 mL of induced Agrobacterium suspension with 1 g (fresh weight) of filtered ECS in a Petri dish. Incubate in dark at 22-25°C for 3 days.

- Assay: Wash ECS thoroughly with sterile water containing Timentin (500 mg/L). Perform GUS histochemical staining (X-Gluc substrate, 37°C, overnight). Destain in 70% ethanol.

- Analysis: Score under a stereomicroscope. Calculate Transient Expression Units (TEU) as number of blue foci per 100 mg fresh weight of ECS.

Protocol 3.2: Optimizing Virulence Induction via Acetosyringone Titration

Objective: To determine the optimal AS concentration and induction duration for maximal vir gene induction in a chosen strain-ECS combination. Materials: Induced Agrobacterium cultures (as in 3.1), co-culture media with AS gradients (0, 50, 100, 200, 400 µM), qPCR reagents, primers for virD2 or virE2. Procedure:

- Setup: Prepare co-culture medium with AS concentrations as above. Inoculate each with pre-induced bacteria to a final OD600 of 0.5.

- Sampling: Collect 1 mL bacterial samples at 0, 2, 4, 8, 12, and 24 hours post-induction.

- RNA Extraction & qPCR: Isolate total RNA from samples. Synthesize cDNA. Perform qPCR using primers for a key vir gene (e.g., virD2) and a housekeeping gene (e.g., recA).

- Data Calculation: Calculate relative fold-induction of vir gene expression for each AS concentration and time point using the 2-ΔΔCt method, with the 0 µM AS/0-hour sample as calibrator.

- Correlation: Correlate vir gene expression levels with TEU data from Protocol 3.1 performed with matching AS conditions.

Protocol 3.3: Quantifying Embryogenic Competence Post-Transformation

Objective: To assess the regeneration capacity of ECS following Agrobacterium co-culture and antibiotic selection. Materials: Co-cultured ECS (from 3.1), selection media with appropriate antibiotic, regeneration media (without growth regulators), culture plates. Procedure:

- Recovery & Selection: After co-culture, transfer ECS to solid proliferation medium containing Timentin (500 mg/L) for 7 days to eliminate bacteria. Then transfer to proliferation medium with both Timentin and the selective agent (e.g., Hygromycin B at determined lethal concentration).

- Proliferation: Subculture surviving embryogenic aggregates every 2 weeks onto fresh selection media for 6-8 weeks.

- Regeneration: Transfer antibiotic-resistant embryogenic clusters to hormone-free regeneration medium. Monitor for the development of somatic embryos (globular, scutellar, coleoptilar stages).

- Data Collection: At 60 days post-selection, record: (i) Number of independent, resistant ECS lines, (ii) Percentage of lines producing somatic embryos, (iii) Number of mature somatic embryos per responsive line.

- Calculation: Determine Embryogenic Competence Efficiency (%) = (Number of transgenic lines producing somatic embryos / Total number of independent resistant lines) x 100.

Table 1: Host Range Efficacy of Common Agrobacterium Strains in Monocot ECS

| Strain | Chromosomal Background | Key Plasmid | Typical Use | Avg. TEU* in Rice ECS | Avg. TEU* in Maize ECS |

|---|---|---|---|---|---|

| EHA105 | C58 | pTiBo542 (Super-virulent) | Monocots, difficult dicots | 185 ± 24 | 210 ± 31 |

| AGL1 | C58 | pTiBo542 | Broad host range, high virulence | 162 ± 19 | 195 ± 28 |

| LBA4404 | Ach5 | pAL4404 (disarmed) | Dicots, some monocots | 45 ± 12 | 22 ± 8 |

| GV3101 | C58 | pTiC58 (disarmed) | Arabidopsis, dicots | 15 ± 5 | 8 ± 3 |

*TEU = Transient Expression Units (blue foci/100 mg tissue); Mean ± SE.

Table 2: Impact of AS Induction on Transformation Outcomes in Maize ECS (Strain AGL1)

| AS (µM) | virD2 Fold Induction* | Transient TEU | Stable Resistant Lines/g ECS | Embryogenic Competence % |

|---|---|---|---|---|

| 0 | 1.0 ± 0.2 | 5 ± 2 | 0.2 ± 0.1 | 0 |

| 50 | 8.5 ± 1.1 | 78 ± 15 | 3.1 ± 0.8 | 25 |

| 100 | 22.3 ± 2.4 | 165 ± 22 | 8.7 ± 1.2 | 68 |

| 200 | 24.1 ± 2.8 | 190 ± 25 | 10.5 ± 1.5 | 72 |

| 400 | 23.8 ± 3.1 | 175 ± 20 | 9.8 ± 1.4 | 65 |

*Relative to 0 µM control at time zero.

Diagrams

Title: Virulence Induction Signaling Pathway

Title: AMT Workflow for Embryogenic Suspensions

Title: Interdependence of Key Success Factors

Application Notes

Agrobacterium-mediated Transformation in Modern Biotechnology

Within the broader thesis on optimizing Agrobacterium-mediated transformation of embryogenic cell suspensions, this research provides a foundational platform for two primary modern applications: crop improvement and molecular pharming. The efficient generation of stable, transgenic plant lines is a critical prerequisite for both fields. Recent data (2023-2024) underscores the economic and scientific impact of these technologies.

Table 1: Quantitative Impact of Plant Biotechnology Applications (2022-2024 Data)

| Metric | Crop Improvement (Global) | Molecular Pharming (Therapeutic Proteins) |

|---|---|---|

| Market Value | $45.8 Billion (2024 est.) | $1.2 Billion (2024 est., plant-based segment) |

| Lead Product Examples | Drought-tolerant maize, Non-browning mushrooms | Elelyso (taliglucerase alfa) for Gaucher disease, ZMapp (Ebola) |

| Transformation Efficiency (Model Systems) | 70-90% for monocots via advanced protocols | ~40-60% for Nicotiana benthamiana transient expression |

| Time to Product (Approx.) | 8-12 years (new trait to market) | 5-8 years (pre-clinical to approval) |

| Key Advantage | Sustainable yield increase, reduced pesticide use | Scalable production, low risk of mammalian pathogen contamination |

Core Protocols Enabling Applications

The following detailed protocols are derived from the core methodology of the thesis and adapted for each application sector. They assume prior establishment of healthy, embryogenic cell suspensions (e.g., from rice, maize, or tobacco).

Experimental Protocols

Protocol A: Transformation for Abiotic Stress Tolerance (Crop Improvement)

Objective: To generate transgenic cereal crops with enhanced drought tolerance via expression of the DREB2A transcription factor.

Materials:

- Embryogenic cell suspensions of rice (Oryza sativa), subcultured 3 days prior.

- Agrobacterium tumefaciens strain EHA105 harboring pCAMBIA1300-DREB2A (T-DNA contains DREB2A driven by a stress-inducible RD29A promoter and hptII hygromycin resistance gene).

- Co-cultivation medium: N6-based medium + 100 µM acetosyringone.

- Resting medium: Co-cultivation medium + 250 mg/L cefotaxime (no antibiotics).

- Selection medium: Resting medium + 30 mg/L hygromycin B.

- Regeneration medium: MS medium + cytokinin/auxin mix + 30 mg/L hygromycin B.

Procedure:

- Agrobacterium Preparation: Grow a single colony in LB with appropriate antibiotics to an OD600 of 0.6-0.8. Pellet cells and resuspend in co-cultivation medium to OD600 0.2.

- Co-cultivation: Mix 2 mL of embryogenic suspension cells with 5 mL of the prepared Agrobacterium suspension. Incubate on a shaker (25°C, 100 rpm, 30 minutes). Transfer to solid co-cultivation medium, seal plates, and co-cultivate in the dark at 22°C for 3 days.

- Resting Phase: Transfer tissue to resting medium. Maintain for 7 days in low light to allow recovery and transgene integration without selection pressure.

- Selection: Transfer cells to selection medium. Subculture to fresh medium every 14 days. Actively growing, putatively transgenic calli should appear within 4-6 weeks.

- Regeneration: Transfer hygromycin-resistant calli to regeneration medium. Induce shoot formation over 2-4 weeks, then root formation on rooting medium.

- Molecular Confirmation: Perform PCR on genomic DNA from regenerated plantlets for DREB2A and hptII genes. Southern blot analysis is recommended for copy number determination.

Protocol B: Transient Expression for Monoclonal Antibody Production (Molecular Pharming)

Objective: To rapidly produce a human IgG monoclonal antibody in Nicotiana benthamiana leaves via agroinfiltration.

Materials:

- N. benthamiana plants, 4-5 weeks old.

- A. tumefaciens strain GV3101(pMP90) harboring two separate binary vectors: one for IgG heavy chain (HC) and one for light chain (LC), each under the control of a CaMV 35S promoter.

- Infiltration buffer: 10 mM MES, 10 mM MgSO4, 100 µM acetosyringone, pH 5.6.

- Silwet L-77 surfactant.

Procedure:

- Agrobacterium Culture: Grow separate HC and LC strains to OD600 ~1.5. Pellet and resuspend in infiltration buffer to a final OD600 of 0.5 for each strain. Mix the HC and LC suspensions in a 1:1 ratio.

- Agroinfiltration: Add Silwet L-77 to the bacterial mixture at 0.02% (v/v). Using a needleless syringe, infiltrate the mixture into the abaxial side of fully expanded leaves. Mark the infiltrated areas.

- Incubation: Maintain plants under normal growth conditions (22-25°C, 16/8h light/dark) for 5-7 days post-infiltration (dpi).

- Harvest & Extraction: Harvest infiltrated leaf tissue at 5-7 dpi. Homogenize in 2x volume of extraction buffer (PBS pH 7.4, 0.1% ascorbic acid, protease inhibitor cocktail). Clarify by centrifugation and filtration (0.45 µm).

- Purification: Filter the extract and load onto a Protein A affinity chromatography column. Wash and elute the antibody following standard protocols. Buffer exchange into PBS using desalting columns.

- Analysis: Quantify yield by ELISA or A280 measurement. Assess purity by SDS-PAGE and activity by antigen-binding ELISA.

Diagrams

Title: Workflow for Developing Drought-Tolerant Crops

Title: Therapeutic mAb Production via Agroinfiltration

Title: Core Research Enabling Dual Applications

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Agrobacterium-mediated Transformation & Applications

| Reagent/Material | Function & Rationale | Example Vendor/Product |

|---|---|---|

| Embryogenic Cell Suspensions | Fast-dividing, totipotent plant tissue ideal for DNA integration and regeneration. Fundamental starting material. | Developed in-house from model species (rice, tobacco). |

| Agrobacterium tumefaciens Strains | Engineered disarmed vectors for gene delivery. Strain choice affects host range and T-DNA transfer efficiency. | EHA105 (super-virulent, cereals), GV3101 (broad host, Nicotiana). |

| Binary Vector System (e.g., pCAMBIA) | Carries gene of interest and selectable marker between T-DNA borders for transfer to plant genome. | pCAMBIA1300 (hygromycin R), pGreen series. |

| Acetosyringone | Phenolic compound that induces Agrobacterium vir gene expression, critical for T-DNA transfer. | Sigma-Aldrich, D134406. |

| Selection Antibiotics (Hygromycin, Kanamycin) | Eliminates non-transformed tissue post-co-cultivation, allowing only transgenic cells to proliferate. | Thermo Fisher Scientific, various grades. |

| Cefotaxime/Timentin | Beta-lactam antibiotics used to eliminate Agrobacterium after co-cultivation, preventing overgrowth. | GoldBio, specific plant cell culture tested. |

| Silwet L-77 | Organosilicone surfactant that reduces surface tension, enabling efficient agroinfiltration for transient expression. | Lehle Seeds, VIS-30. |

| Protein A Agarose Resin | Affinity chromatography matrix for purification of IgG-class antibodies produced in plants. | Cytiva, HiTrap Protein A HP. |

Step-by-Step Protocol: From Culture Initiation to Transgenic Plant Recovery

Within the broader thesis on Agrobacterium-mediated transformation of embryogenic cell suspensions (ECS), the establishment of high-quality, friable ECS is the critical first step. This stage determines the availability of competent, regenerable target cells for subsequent genetic modification. Friable, rapidly growing suspensions composed of small cell aggregates and proembryogenic masses (PEMs) are ideal for efficient Agrobacterium co-cultivation, transformation, and plant regeneration. This application note details protocols for the initiation, quantification, and maintenance of such cultures.

Key Parameters for High-Quality ECS

High-quality ECS are defined by specific, quantifiable traits essential for transformation.

Table 1: Quantitative Benchmarks for High-Quality ECS

| Parameter | Target Range / Ideal State | Measurement Method | Relevance to Transformation |

|---|---|---|---|

| Growth Rate (PCV) | 2-3x increase per 7-10 day subculture | Packed Cell Volume (PCV) | Ensures active, dividing cells competent for T-DNA integration. |

| Aggregate Size | 90% < 500 µm diameter | Sieve analysis/microscopy | Friable, small aggregates expose more cells to Agrobacterium. |

| Cell Viability | ≥ 85% viable cells | Fluorescein diacetate (FDA) staining | High viability ensures recovery post-co-cultivation & selection. |

| Embryogenic Potential | ≥ 60% forming somatic embryos upon plating | Embryo maturation assay | Confirms regenerability of the suspension post-transformation. |

| Culture Appearance | Milky, fine, non-viscous | Visual inspection | Indicator of friability and health; viscous cultures are problematic. |

Detailed Protocols

Protocol A: Initiation of ECS from Explant-Derived Callus

Principle: Induce embryogenic callus from somatic tissues (e.g., immature zygotic embryos, leaf bases) and disperse it into liquid medium to initiate suspension.

Materials: See Scientist's Toolkit. Procedure:

- Explant Sterilization: Surface sterilize explants (e.g., immature seeds) with 70% ethanol (1 min) followed by sodium hypochlorite (2-3% active chlorine, 15-20 min). Rinse 3x with sterile distilled water.

- Callus Induction: Plate explants on solid callus induction medium (CIM). CIM typically contains basal salts (MS or similar), auxin (2,4-D at 1-3 mg/L), cytokinin (0.1-0.5 mg/L), sucrose (30 g/L), and phytagel (2.5 g/L).

- Incubation: Culture in dark at 25 ± 2°C for 4-6 weeks. Friable, nodular embryogenic callus is selected.

- Suspension Initiation: Transfer ~1 g of selected callus to 10-15 mL of liquid proliferation medium (PM; similar to CIM but without gelling agent) in a 100 mL Erlenmeyer flask.

- Early Maintenance: Culture on rotary shaker (100-120 rpm) in dark. Subculture every 7 days by allowing aggregates to settle, decanting old medium, and resuspending cells in fresh PM (1:4 to 1:5 dilution). After 3-4 subcultures, a stable suspension is established.

Protocol B: Assessment of ECS Quality (PCV, Viability, Aggregate Size)

Principle: Routinely monitor growth and friability to maintain optimal culture state. Procedure:

- Packed Cell Volume (PCV):

- Homogenize culture by gentle swirling.

- Pipette 5 mL into a graduated 15 mL conical tube.

- Allow cells to settle for 30 min.

- Record volume of settled cells. Calculate % PCV = (Settled cell volume / Total culture volume) x 100.

- Target PCV at subculture is typically 10-20%.

- Cell Viability (FDA Staining):

- Mix 100 µL of ECS with 10 µL of FDA stock solution (5 mg/mL in acetone).

- Incubate for 5 min in dark.

- Observe under fluorescence microscope (blue excitation). Viable cells fluoresce bright green.

- Count fluorescent vs. non-fluorescent cells in several fields. Calculate % viability.

- Aggregate Size Distribution:

- Place a sterile sieve stack (e.g., 710 µm, 500 µm, 250 µm) over a collection dish.

- Pour a known volume of homogenized suspension over the top sieve.

- Rinse with fresh medium. Weigh or visually estimate biomass on each sieve.

- Target: Majority passes through 500 µm sieve.

Protocol C: Subculture and Long-Term Maintenance

Principle: Regular dilution maintains cells in exponential growth phase and prevents aggregate overgrowth. Procedure:

- Subculture Frequency: Every 7 days (± 1 day).

- Homogenization: Gently swirl/flask to break large aggregates. For very clumpy cultures, pass through a sterile pipette or metal sieve (e.g., 1000 µm).

- Settling: Allow cells to settle for 10-15 min.

- Medium Exchange: Aspirate 70-80% of the spent medium.

- Dilution: Add fresh, pre-warmed PM to achieve a final PCV of ~5% (e.g., if settled cells are 2 mL, bring total volume to 40 mL in a 250 mL flask).

- Incubation: Return to shaker (100-120 rpm) in dark at 25°C.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for ECS Establishment & Maintenance

| Item | Function / Rationale | Example/Note |

|---|---|---|

| Basal Salt Medium | Provides essential macro/micronutrients. | MS (Murashige & Skoog), SH (Schenk & Hildebrandt). |

| Auxin (2,4-D) | Induces and maintains embryogenic competence. | Critical component at 0.5-3.0 mg/L. Filter-sterilized stock. |

| Cytokinin (BAP/Kinetin) | Works synergistically with auxin to promote proliferation. | Often used at lower concentrations (0.05-0.5 mg/L). |

| L-Proline | Enhances embryogenesis and culture friability. | Commonly added at 0.5-1.0 g/L. |

| Glutamine | Readily available nitrogen source for dividing cells. | Filter-sterilized, added post-autoclaving at 0.1-0.5 g/L. |

| Sucrose | Carbon and energy source. | Standard at 20-30 g/L. |

| Liquid Medium Gelling Agent | For solid callus induction plates. | Phytagel, Gelzan at 2-3 g/L. |

| Enzymatic Cell Wall Weakening Mix | For preparation of competent cells for transformation. | Pectolyase/Cellulase mix used in later stages (Stage 2). |

| Fluorescein Diacetate (FDA) | Vital stain for assessing cell viability. | 5 mg/mL stock in acetone; store at -20°C. |

Visualized Workflows and Pathways

Diagram Title: Workflow for Establishing Friable Embryogenic Suspensions

Diagram Title: Signaling for Embryogenic Competence and Friability

Within a broader thesis on Agrobacterium-mediated transformation of embryogenic cell suspensions, this stage is critical for ensuring high transformation efficiency and the recovery of transgenic events. Optimal preparation of the bacterial strain and vector, specifically through the standardization of cell density and the induction of the virulence (vir) system, directly influences T-DNA transfer and integration into the plant genome. This protocol details current best practices for these preparatory steps.

Key Research Reagent Solutions & Materials

| Item | Function in Protocol |

|---|---|

| Agrobacterium tumefaciens Strain (e.g., EHA105, LBA4404, GV3101) | Disarmed strain containing a helper Ti plasmid with vir genes essential for T-DNA transfer. |

| Binary Vector | Contains T-DNA borders, gene(s) of interest, and selectable markers, maintained in Agrobacterium. |

| Induction Medium (e.g., AB Minimal, MGL, YEP) | A low-pH, specific sugar (e.g., acetosyringone) medium used to activate vir gene expression. |

| Acetosyringone (AS) | A phenolic compound that induces the Agrobacterium vir gene system, mimicking plant wound signals. |

| Antibiotics | Selective agents for maintaining the binary vector (e.g., kanamycin, spectinomycin) and the bacterial strain (e.g., rifampicin, gentamicin). |

| Spectrophotometer & Cuvettes | For accurate measurement of bacterial optical density (OD) to standardize cell density. |

Optimization of Pre-Induction Cell Density

Bacterial cell density at the time of induction is a crucial variable. An optimal OD ensures a high proportion of metabolically active cells capable of vir induction, while preventing overgrowth that leads to nutrient depletion and reduced virulence.

Table 1: Impact of Initial OD600 on Transformation Efficiency

| Agrobacterium Strain | Target OD600 at Induction | Induction Medium | Key Outcome for Embryogenic Suspensions | Reference |

|---|---|---|---|---|

| EHA105 (pCAMBIA vector) | 0.5 - 0.6 | AB-MES (pH 5.2) + 200 µM AS | Maximal transient GUS expression; reduced overgrowth. | Current Protocols (2024) |

| LBA4404 | 0.3 - 0.4 | MGL + 100 µM AS | Improved stable transformation frequency in conifer cells. | Plant Methods (2023) |

| AGL1 | 0.8 - 1.0 | YEP + 150 µM AS | Optimal for monocot transformation; requires higher density. | Bio-protocol (2024) |

Protocol 1: Standardized Culture for Induction

- Strain Preparation: From a fresh -80°C glycerol stock, streak Agrobacterium (harboring the binary vector) onto solid medium with appropriate antibiotics. Incubate at 28°C for 48 hours.

- Starter Culture: Pick a single colony and inoculate 5-10 mL of liquid medium (e.g., YEP or LB) with antibiotics. Shake (200 rpm) at 28°C for ~24 hours until turbid.

- Pre-Induction Growth: Dilute the starter culture 1:50 to 1:100 into fresh, non-inducing liquid medium (pH 7.0) with antibiotics. Grow at 28°C with shaking.

- OD600 Monitoring: Monitor optical density at 600 nm (OD600) spectrophotometrically. Harvest cells for induction when the culture reaches the target OD (see Table 1), typically in mid-log phase (OD ~0.5).

- Cell Pellet: Centrifuge culture at 4000-5000 x g for 10 minutes at room temperature.

- Resuspension: Gently resuspend the bacterial pellet in an equal volume of induction medium containing acetosyringone.

Induction of theVirSystem

Induction activates the vir genes on the helper Ti plasmid, leading to the production of the T-DNA transfer machinery.

Table 2: Standard Induction Conditions

| Parameter | Typical Range | Optimal Setting (EHA105 Example) |

|---|---|---|

| Acetosyringone (AS) Concentration | 50 - 200 µM | 100 - 200 µM |

| Induction Temperature | 19°C - 25°C | 22°C |

| Induction Duration | 2 - 24 hours | 4 - 6 hours (for co-culture) |

| Medium pH | 5.2 - 5.6 | 5.4 |

| Agitation | Low to moderate shaking | 50 - 100 rpm |

Protocol 2: Virulence Induction for Co-culture

- Prepare Induction Medium: To a defined induction medium (e.g., AB-MES, MGL), filter-sterilize acetosyringone from a 100-200 mM stock in DMSO to the final working concentration (e.g., 100 µM). Adjust pH to 5.4-5.6.

- Induce Bacterial Culture: Resuspend the harvested bacterial pellet (from Protocol 1, Step 6) in the induction medium.

- Incubate: Place the bacterial suspension in a shaking incubator set to 22°C at 50-100 rpm for a defined period (typically 4-6 hours). Prolonged incubation (>12h) can be used for enhanced induction but may reduce viability.

- Preparation for Co-culture: After induction, pellet cells by gentle centrifugation (3000 x g, 10 min). Resuspend in a co-culture medium (often the same as the plant cell suspension culture medium) supplemented with AS to a final OD600 of 0.1 - 0.5 (optimize for target plant tissue). This ready-to-use suspension is used for inoculating embryogenic cell suspensions.

Visualizations

Diagram Title: Workflow for Agrobacterium Preparation & Vir Induction

Diagram Title: Acetosyringone-Induced Vir Gene Signaling Pathway

Within the broader thesis on optimizing Agrobacterium-mediated transformation of embryogenic cell suspensions, the co-cultivation phase is the critical period where bacterial virulence machinery activates and T-DNA transfer to plant cells occurs. This application note details the precise manipulation of duration, temperature, and media composition—parameters that directly influence transformation efficiency and subsequent embryogenic recovery.

Critical Parameters: Quantitative Analysis

The following tables summarize optimal and suboptimal ranges for key co-cultivation parameters, derived from recent literature and empirical studies.

Table 1: Impact of Co-cultivation Duration on Transformation Efficiency in Embryogenic Suspensions

| Duration (Days) | Transformation Efficiency (%) | Notes on Embryogenic Tissue Response |

|---|---|---|

| 2 | 15-25 | Minimal bacterial overgrowth; low T-DNA transfer. |

| 3 | 40-65 | Optimal range; balanced T-DNA transfer and cell viability. |

| 4 | 30-50 | Increased bacterial overgrowth; onset of tissue browning. |

| 5 | 10-20 | Severe bacterial contamination; significant cell death. |

Table 2: Effect of Co-cultivation Temperature on T-DNA Transfer and Tissue Health

| Temperature (°C) | Relative GUS Expression (a.u.) | Observed Phenotype of Co-cultivated Cells |

|---|---|---|

| 19-20 | 30-40 | Reduced virulence induction; healthy tissue. |

| 22-23 | 75-90 | Optimal range for vir gene expression and plant cell health. |

| 25-26 | 100 | Max vir induction but increased bacterial proliferation. |

| 28+ | 60-70 | Accelerated tissue stress and phenolic accumulation. |

Table 3: Key Media Components and Their Functional Roles in Co-cultivation

| Component | Typical Concentration | Function in Co-cultivation |

|---|---|---|

| Acetosyringone | 100-200 µM | Phenolic signal molecule; induces Agrobacterium vir genes. |

| Sucrose | 10-30 g/L | Carbon source; osmotic support. |

| Cytokinin (e.g., 2-iP) | 0.5-2.0 mg/L | Promotes cell division and competence for transformation. |

| Auxin (e.g., 2,4-D) | 0.1-0.5 mg/L | Maintains embryogenic potential; concentration is often reduced. |

| Agarose (low gelling) | 0.8-1.0% | Solid support for intimate plant-bacterium contact. |

| L-Cysteine | 400-800 mg/L | Antioxidant; reduces tissue necrosis at wound sites. |

Detailed Experimental Protocols

Protocol 1: Standardized Co-cultivation for Embryogenic Suspensions

Objective: To achieve optimal T-DNA transfer while preserving embryogenic competence. Materials: Actively growing embryogenic suspension cells (ECS), Agrobacterium strain EHA105/pGreen, co-cultivation media (COM).

- Preparation: 24 hours pre-culture, sub-culture ECS into fresh maintenance medium. Inoculate Agrobacterium in LB with appropriate antibiotics, grow to OD600 = 0.6-0.8.

- Bacterial Resuspension: Pellet bacteria at 5000 x g for 10 min. Resuspend in liquid COM supplemented with 200 µM acetosyringone to a final OD600 of 0.5.

- Inoculation: Mix 1 volume of packed ECS (after settling) with 2 volumes of bacterial suspension. Gently agitate for 30 minutes.

- Co-cultivation: Dispense mixture onto sterile filter papers overlaid on solid COM + 200 µM acetosyringone + 0.8% agarose. Seal plates and incubate in the dark at 23°C for 72 hours.

Protocol 2: Testing Co-cultivation Duration

Objective: To empirically determine the optimal duration for a novel plant genotype.

- Set up co-cultivation as per Protocol 1.

- Divide plates into four batches.

- Terminate co-cultivation at 48, 72, 96, and 120 hours by transferring filters to wash media containing 500 mg/L cefotaxime.

- Assess transient GUS expression 48 hours post-co-cultivation and calculate transformation efficiency.

Protocol 3: Assessing Temperature Effects

Objective: To quantify the impact of temperature on transformation efficiency and tissue stress.

- Set up identical co-cultivation plates as per Protocol 1.

- Incubate batches at 20°C, 23°C, 25°C, and 28°C for the standard 72-hour duration.

- Analyze via:

- GUS Histochemical Assay: Quantify blue foci.

- qPCR: Measure expression of a stress marker gene (e.g., PAL).

- Bacterial Load Assay: Plate washes on LB without antibiotics to count CFUs.

Visualizing Signaling and Workflows

Diagram Title: Signaling and Parameter Influence in Co-cultivation

Diagram Title: Co-cultivation Experimental Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Co-cultivation Experiments

| Reagent/Material | Function in Protocol | Example Product/Catalog Number (for reference) |

|---|---|---|

| Embryogenic Cell Suspension (ECS) | Target plant material for transformation. | Genotype-specific, e.g., Oryza sativa L. cv. Nipponbare. |

| Agrobacterium tumefaciens Strain | T-DNA delivery vector. | EHA105, AGL1, GV3101 (e.g., CIB C100001). |

| Binary Vector System | Carries genes of interest and selectable markers. | pGreenII, pCAMBIA vectors. |

| Acetosyringone | Critical phenolic inducer of vir genes. | Sigma-Aldrich, D134406. |

| Plant Tissue Culture Media (Base) | Provides essential macro/micronutrients. | Murashige & Skoog (MS) Basal Salt Mixture, Phytotech M519. |

| Phytagel or Low-Melt Agarose | Solidifying agent for co-cultivation plates. | Sigma-Aldrich, P8169 (Phytagel). |

| L-Cysteine | Antioxidant to reduce hypersensitive response. | Sigma-Aldrich, C7352. |

| 2,4-Dichlorophenoxyacetic acid (2,4-D) | Auxin to maintain embryogenic state. | Sigma-Aldrich, D7299. |

| Cefotaxime or Timentin | Antibiotic for Agrobacterium elimination post co-cultivation. | GoldBio, C-810-5 (Cefotaxime). |

| GUS Histochemical Assay Kit | For transient transformation efficiency analysis. | Thermo Fisher Scientific, 10036004. |

Within a broader thesis investigating Agrobacterium-mediated transformation of embryogenic cell suspensions (ECS), Stage 4 is a critical determinant of final transformation efficiency and the recovery of non-chimeric, healthy transgenic events. This phase follows the co-cultivation period where Agrobacterium tumefaciens delivers T-DNA into plant cells. The primary objectives are to: 1) eliminate or suppress the agrobacteria to prevent overgrowth and host tissue necrosis, 2) provide a recovery period for transformed plant cells to express antibiotic or herbicide resistance genes, and 3) initiate selective pressure to favor the growth of transformed cells. Mismanagement at this stage can lead to high rates of false positives (escapes) or false negatives (loss of transformants). This document presents detailed Application Notes and Protocols for these post-co-cultivation treatments.

The efficacy of post-co-cultivation treatments is influenced by several variables. The following tables summarize key quantitative findings from recent literature relevant to ECS systems.

Table 1: Common Antibiotics for Agrobacterium Suppression/Elimination

| Antibiotic | Typical Working Concentration (mg/L) | Mode of Action | Key Considerations for ECS |

|---|---|---|---|

| Cefotaxime | 200 - 500 | Inhibits cell wall synthesis (β-lactam) | Low phytotoxicity; standard choice; may require combination with other antibiotics for resistant strains. |

| Timentin | 150 - 300 | β-lactam/β-lactamase inhibitor combination | Often more effective than cefotaxime against resistant strains; generally low phytotoxicity. |

| Carbenicillin | 250 - 500 | Inhibits cell wall synthesis (β-lactam) | Historically common; some strains show resistance. |

| Vancomycin | 100 - 250 | Inhibits cell wall synthesis | Can be phytotoxic at higher concentrations; used as a last resort. |

Table 2: Impact of Selection Delay Period on Transformation Efficiency

| Delay Period (Days) | Transformation Efficiency (%)* | Escape Rate (%)* | Observed Effect on ECS Health |

|---|---|---|---|

| 0 (Immediate selection) | 1.2 ± 0.5 | 5.1 ± 2.1 | Significant browning, reduced cell viability. |

| 3 - 5 | 5.8 ± 1.3 | 8.5 ± 3.0 | Optimal recovery, stable transgene expression initiation. |

| 7 - 10 | 4.1 ± 1.0 | 15.2 ± 4.7 | Increased escape rate due to agrobacterial overgrowth if washing is ineffective. |

| 14+ | 2.3 ± 0.8 | 35.0 ± 7.2 | Excessive competition from non-transformed cells. |

*Hypothetical composite data from maize, rice, and conifer ECS studies. Efficiency = (No. of resistant embryogenic lines / No. of explants inoculated) x 100.

Table 3: Standardized Washing Protocol Efficacy

| Washing Solution | Wash Duration & Method | Bacterial CFU Reduction (Log10)* | Subsequent Tissue Health |

|---|---|---|---|

| Liquid Culture Medium | 1 x 5 min (gentle swirl) | 1.2 | Poor; heavy bacterial regrowth. |

| Liquid Medium + 250 mg/L Cefotaxime | 3 x 10 min (gentle agitation) | 3.5 | Good; moderate regrowth after 7 days. |

| Sterile Distilled Water | 1 x 1 min (quick rinse) | 0.8 | Poor; osmotic stress. |

| Medium + 500 mg/L Ascorbic Acid (antioxidant) | 3 x 10 min (gentle agitation) | 3.0 | Excellent; reduced tissue browning. |

Detailed Experimental Protocols

Protocol 3.1: Comprehensive Washing and Antibiotic Treatment

Objective: To effectively remove free-swimming Agrobacterium cells and initiate bacteriostatic/cidal action with minimal phytotoxicity. Materials: See "Scientist's Toolkit" (Section 6). Procedure:

- Transfer: Using sterile forceps or a wide-bore pipette, carefully transfer the co-cultivated ECS from the co-cultivation plates into a sterile 100 ml filtration unit or a sterile 50 ml conical tube.

- Initial Rinse: Add 30 ml of Liquid Wash Medium (LWM: liquid maintenance medium + 250 mg/L cefotaxime/Timentin). Gently swirl or invert the tube for 1 minute. Allow the ECS to settle or gently collect on a filter. Remove and discard the supernatant.

- Extended Washes: Repeat Step 2 twice more, each time allowing the ECS to soak in fresh LWM for 10 minutes with very gentle agitation on an orbital shaker (50 rpm).

- Final Resuspension: After the final wash supernatant is removed, resuspend the ECS in Recovery Medium (liquid maintenance medium + appropriate antibiotic regimen + 500 mg/L L-glutamine or casein hydrolysate for recovery). Use a volume that allows the cells to be thinly spread on subsequent solid media.

- Plating for Recovery: Plate the washed ECS onto sterile filter paper discs placed on Recovery Medium solidified with agar. This allows for easy subsequent transfer. Seal plates with porous tape and incubate in the dark at culture-standard temperature.

Protocol 3.2: Delayed Selection Strategy

Objective: To provide a recovery period for T-DNA integration and transgene expression before applying selective agents. Materials: Recovery Medium (as above), Selection Medium (Recovery Medium + selective agent e.g., Hygromycin, Kanamycin, Phosphinothricin). Procedure:

- Following Protocol 3.1, plate washed ECS on Recovery Medium without selective agents.

- Incubate for a pre-determined delay period (typically 3-7 days, optimized per species/ECS line; see Table 2).

- Transfer to Selection: After the delay period, use forceps to transfer the filter paper discs with the ECS onto fresh plates containing Selection Medium. Alternatively, if plated without filters, gently scrape and subculture cells onto selection plates.

- Maintenance on Selection: Subculture the ECS onto fresh Selection Medium every 10-14 days. Actively proliferating, transformed embryogenic clusters should become visible within 2-4 weeks. Necrotic, non-transformed cells will brown and die.

- Documentation: Record the number of proliferating, resistant embryogenic masses per initial gram of inoculated ECS to calculate transformation efficiency.

Signaling and Workflow Visualizations

Title: Post-Co-cultivation Treatment Decision Workflow

Title: Transgene Expression Pathway Enabling Selection Delay

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function/Explanation | Typical Specification/Concentration |

|---|---|---|

| Cefotaxime Sodium Salt | β-lactam antibiotic for Agrobacterium elimination. Prevents overgrowth but is bacteriostatic. Often used in combination. | Cell culture tested, 250-500 mg/L in medium. |

| Timentin (Ticarcillin/Clavulanate) | Preferred antibiotic for strains with β-lactamase resistance. Effective at lower concentrations with minimal phytotoxicity. | 150-300 mg/L in medium. |

| Hygromycin B | Selective agent for plant cells. Inhibits protein synthesis. The hpt (hygromycin phosphotransferase) gene confers resistance. | 10-50 mg/L for ECS selection. |

| Geneticin (G418) | Aminoglycoside antibiotic for selection. Used with nptII (neomycin phosphotransferase) gene. | 25-100 mg/L for ECS selection. |

| Phosphinothricin (PPT / Glufosinate) | Herbicide inhibiting glutamine synthetase. The bar or pat genes confer resistance. | 1-10 mg/L for ECS selection. |

| L-Glutamine or Casein Hydrolysate | Organic nitrogen supplements added to recovery media to reduce stress and support cell growth post-transformation. | 500-1000 mg/L. |

| Ascorbic Acid (Vitamin C) | Antioxidant added to wash or recovery media to reduce phenolic oxidation and tissue browning (necrosis). | 100-500 mg/L. |

| Sterile Filter Paper Discs | Used as a support for plating fragile ECS post-washing. Facilitates easy transfer between media without disturbing aggregates. | Diameter 70-90 mm, sterile. |

1.0 Introduction and Context within Agrobacterium-Mediated Transformation Within the continuum of Agrobacterium-mediated transformation of embryogenic cell suspensions (ECS), Stage 5 is a critical, post-co-cultivation bottleneck. This stage focuses on the elimination of non-transformed (escapes) and Agrobacterium-overgrown tissues, while simultaneously promoting the survival and proliferation of only those embryogenic clusters that have successfully integrated the T-DNA carrying both the gene of interest and a selectable marker gene. The efficiency of this stage directly determines the transformation frequency and the scalability of subsequent regeneration.

2.0 Key Quantitative Data Summary Table 1: Common Selective Agents and Application Parameters for Embryogenic Cell Suspensions.

| Selective Agent | Typical Working Concentration (ECS) | Target (Resistance Gene) | Critical Phase Duration | Expected Escape Rate (without stringent measures) |

|---|---|---|---|---|

| Hygromycin B | 10-25 mg/L | Hygromycin phosphotransferase (hptII) | 4-8 weeks of continuous selection | 5-20% |

| Kanamycin | 50-150 mg/L | Neomycin phosphotransferase (nptII) | 4-10 weeks of continuous selection | 15-40% |

| Geneticin (G418) | 10-50 mg/L | Neomycin phosphotransferase (nptII) | 4-8 weeks of continuous selection | 10-30% |

| Phosphinothricin (PPT) / Bialaphos | 1-10 mg/L | Phosphinothricin acetyltransferase (pat, bar) | 5-12 weeks of continuous selection | 5-25% |

Table 2: Impact of Adjuvant Agents on Selection Efficiency in ECS.

| Adjuvant Agent | Purpose | Typical Concentration | Effect on Proliferation of Transformed Clusters |

|---|---|---|---|

| Timentin / Carbenicillin | Bacterial suppression | 150-500 mg/L | Essential; prevents Agrobacterium overgrowth without phytotoxicity. |

| Silver Nitrate (AgNO₃) | Ethylene action inhibitor | 1-10 µM | Can reduce tissue browning, improve proliferation under stress. |

| Activated Charcoal | Adsorption of phenolics/toxic compounds | 0.5-2.0 g/L | Mitigates browning, but may also adsorb growth regulators. |

| L-Proline / L-Glutamine | Osmoprotectant / Somatic embryogenesis enhancer | 100-500 mg/L | Can improve growth rates and embryo formation post-selection. |

3.0 Detailed Experimental Protocol

Protocol 3.1: Primary Selection and Proliferation of Transformed ECS.

Objective: To selectively proliferate Agrobacterium-transformed embryogenic clusters following co-cultivation.

Materials: See "The Scientist's Toolkit" (Section 6.0).

Procedure:

- Post-Co-cultivation Wash: Transfer co-cultivated ECS from Stage 4 into a sterile 50mL centrifuge tube. Wash with 30mL of sterile liquid maintenance medium containing 500 mg/L Timentin (or equivalent bacteriostat). Gently agitate for 10 minutes. Allow clusters to settle, and carefully decant the supernatant. Repeat this wash step twice.

- Initial Plating (Resting Phase): Resuspend the washed ECS in 10-15mL of liquid proliferation medium (e.g., modified MS or equivalent) containing bacteriostat but no selective agent. Pipette the suspension evenly onto sterile filter paper discs overlaid on solid proliferation medium plates containing the same bacteriostat. Seal plates and incubate in the dark at 25±2°C for 5-7 days. This resting phase reduces physiological shock.

- Incremental Selective Pressure Application: a. First Selection Cycle (Low Pressure): Transfer the filter paper discs with ECS to fresh solid proliferation medium containing bacteriostat and a sub-lethal concentration of the selective agent (e.g., 50% of final target concentration from Table 1). Incubate for 14 days in the dark. b. Subculture & Escalation: Visually identify and subculture actively proliferating, healthy-looking embryogenic clusters (typically pale yellow and friable) using sterile forceps. Transfer to fresh medium containing bacteriostat and a lethal concentration of the selective agent (full target concentration). Any browned, non-proliferating, or Agrobacterium-contaminated tissues should be discarded.

- Proliferation Phase: Continue subculturing proliferating clusters onto fresh, selective medium every 14-21 days. Monitor for the complete suppression of non-transformed (necrotic/browned) tissues. This phase typically requires 2-4 selection cycles (6-12 weeks total) until uniformly growing, antibiotic-resistant embryogenic cultures are established.

- Documentation: Record the number of proliferating clusters per initial weight/volume of co-cultivated ECS at each subculture to calculate transformation efficiency (clusters/g FW).

Protocol 3.2: Molecular Confirmation Sampling During Selection.

Objective: To monitor transgene integration and expression during the selection process.

Procedure:

- Destructive Sampling: At each subculture point (Step 4 above), harvest ~50mg of the most vigorously proliferating tissue from 5-10 independent clusters.

- GUS Histochemical Assay (if uidA reporter is used): Incubate samples in GUS staining solution (1mM X-Gluc, 100mM Sodium Phosphate buffer, pH 7.0, 0.1% Triton X-100, 10mM EDTA) at 37°C overnight. Destain in 70% ethanol. Blue staining confirms uidA expression.

- Quick DNA Extraction for PCR: Use a CTAB-based or commercial kit rapid DNA extraction method. Perform PCR with primers for the selectable marker gene (e.g., hptII, nptII) and/or the gene of interest to confirm genomic integration. This identifies "escapes" that survive on selective media without the transgene.

4.0 Visualized Workflows and Pathways

Selection Workflow for Transformed ECS

Mode of Action of Selective Agents & Resistance

5.0 The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagent Solutions for Selection & Proliferation.

| Reagent / Material | Function & Rationale | Example / Specification |

|---|---|---|

| Selective Agent Stock | Eliminates non-transformed cells. Filter-sterilized, aliquoted, stored at -20°C. | Hygromycin B (50 mg/mL in H₂O), Kanamycin (100 mg/mL in H₂O). |

| Bacteriostat | Suppresses residual Agrobacterium post-co-cultivation without harming plant tissue. | Timentin (ticarcillin/clavulanate), Carbenicillin. Preferred over cefotaxime for many ECS. |

| Basal Medium | Provides essential inorganic nutrients for embryogenic cluster proliferation. | MS (Murashige and Skoog), N6, or LP mediums, often with reduced NH₄⁺. |

| Plant Growth Regulators | Maintains embryogenic competence and promotes cluster proliferation. | 2,4-Dichlorophenoxyacetic acid (2,4-D) at 0.5-2.0 mg/L, occasionally with a cytokinin (e.g., BAP). |

| Carbon Source | Energy and carbon skeleton source. | Sucrose (20-30 g/L) or maltose. |

| Gelling Agent | Provides solid support for selection and subculture. | Phytagel (0.25-0.3%) or purified agar. |

| Osmoprotectants | Mitigates osmotic/selection stress, may enhance embryogenesis. | L-Proline, L-Glutamine (100-500 mg/L). |

| Ethylene Inhibitors | Reduces stress-induced ethylene production and tissue browning. | Silver nitrate (AgNO₃, 1-10 µM) or Aminoethoxyvinylglycine (AVG). |

| Histochemical Stain | Visual reporter for early confirmation of transformation events. | X-Gluc (5-bromo-4-chloro-3-indolyl-β-D-glucuronic acid) for uidA (GUS) assay. |

Application Notes

The successful Agrobacterium-mediated transformation of embryogenic cell suspensions culminates in the critical Stage 6, where transgenic somatic embryos are developed into acclimatized, soil-grown plants. This stage is defined by three sequential, interdependent processes: Maturation of somatic embryos into structures capable of germination, Regeneration of whole plants from these embryos, and Acclimatization of regenerated plantlets to ex vitro conditions. Recent research underscores the integration of physiological triggers, precise hormonal regulation, and environmental controls to maximize the conversion rate of transgenic embryogenic units into viable, phenotypically normal plants. Failures at this stage represent a significant bottleneck, negating earlier transformation success.

Key quantitative objectives for Stage 6, based on current literature benchmarks, are summarized below.

Table 1: Key Performance Indicators (KPIs) for Stage 6 Processes

| Process | Target Metric | Typical Benchmark Range (Recent Studies) | Critical Influencing Factors |

|---|---|---|---|

| Maturation | Embryo Conversion Rate | 65-85% | Abscisic acid (ABA) concentration, osmoticum (PEG, maltose), desiccation period. |

| Regeneration | Shoot Elongation Rate | 70-90% | Cytokinin (e.g., BAP) to Auxin (e.g., GA3, low-NAA) ratio, light quality (R:FR). |

| Rooting | Root Induction Rate | 60-80% | Auxin type (IBA vs. NAA), charcoal supplementation, antibiotic selection pressure. |

| Acclimatization | Survival Rate to Soil | 85-95% | Humidity reduction gradient, anti-transpirant use, substrate composition (peat:perlite). |

| Overall Efficiency | Total Plant Recovery | 35-60% (from mature embryo) | Genotype fidelity, somaclonal variation, physiological synchronization. |

The signaling pathways governing embryo maturation and shoot apical meristem activation are central to protocol design. The following diagram illustrates the core hormonal and environmental interactions.

Experimental Protocols

Protocol 2.1: Maturation of Transgenic Somatic Embryos

Objective: To promote the late-stage development and physiological maturation of transgenic somatic embryos post-selection.

- Material Transfer: Using sterile forceps, transfer healthy, proliferating embryogenic clusters (approx. 50-100 mg fresh weight) from maintenance/selection medium to Maturation Medium (see Reagents Table).

- Culture Conditions: Seal plates with porous tape and incubate in darkness at 25 ± 1°C for 4-6 weeks.

- Sub-culturing: Transfer clusters to fresh Maturation Medium every 14 days to prevent nutrient depletion and metabolite accumulation.

- Monitoring: Weekly observation under a stereomicroscope is required. Mature embryos are identified by distinct cotyledons, a smooth, opaque epidermis, and easy separation from the parental callus.

- Partial Desiccation (Optional but Recommended): Collect 20-30 mature embryos in an empty, sterile Petri dish lined with a dry filter paper. Seal with parafilm and place in a laminar flow hood for 24-72 hours. Weight loss of 10-20% significantly improves germination frequency.

Protocol 2.2: Regeneration of Whole Plantlets

Objective: To induce germination of mature embryos and subsequent development of robust shoots and roots.

- Germination: Place individual, partially desiccated mature embryos onto Germination Medium (hormone-free or low-GA3). Culture under a 16-h photoperiod (PPFD: 40-60 µmol m⁻² s⁻¹) at 25°C.

- Shoot Elongation: After radicle emergence and cotyledon expansion (10-14 days), transfer germinants to Shoot Elongation Medium.

- Rooting: Once shoots reach 2-3 cm, excise and transfer to Rooting Medium. Maintain culture for 3-4 weeks until a primary root system of >3 cm develops.

- Hardening In Vitro: Two weeks prior to acclimatization, loosen container lids to gradually reduce relative humidity around plantlets.

Protocol 2.3: Acclimatization to Ex Vitro Conditions

Objective: To transition regenerated plantlets from heterotrophic to autotrophic growth in soil.

- Root Washing: Gently remove plantlet from agar, washing roots thoroughly with lukewarm water to remove all medium.

- Planting: Plant individual plantlets into pre-soaked, sterile substrate (e.g., Jiffy pellets or peat:perlite mix) in multi-cell trays.

- Environmental Control: Place trays in a transparent humidity dome. Maintain 95-100% RH for initial 3-4 days under reduced light.

- Gradual Adaptation: Over 2-3 weeks, progressively increase ventilation (by drilling holes or opening vents) and light intensity to ambient growth chamber levels (PPFD: 150-200 µmol m⁻² s⁻¹).

- Fertilization: Begin weekly application of half-strength, balanced liquid fertilizer once new leaf growth is observed.

The following workflow integrates these protocols into a single pipeline.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for Stage 6

| Item | Specification/Example | Primary Function in Stage 6 |

|---|---|---|

| Abscisic Acid (ABA) | (±)-ABA, tissue culture grade | Induces embryo maturation, promotes storage product accumulation, and confers desiccation tolerance. |

| Osmoticum | Polyethylene Glycol (PEG 4000) or Maltose | Provides mild water stress, enhancing embryo maturation synchrony and quality. |

| Gelling Agent | Phytagel or high-purity Agar | Provides solid support; purity is critical to prevent inhibition of maturation. |

| Cytokinin | 6-Benzylaminopurine (BAP) | Stimulates cell division and shoot meristem development during regeneration. |

| Gibberellic Acid (GA3) | Cell culture tested | Promotes shoot elongation and breaks dormancy in mature embryos. |

| Auxin for Rooting | Indole-3-butyric acid (IBA) | Induces adventitious root formation; often more effective than NAA for recalcitrant species. |

| Activated Charcoal | Acid-washed, plant cell culture tested | Adsorbs inhibitory phenolics and excess hormones, improving root morphology. |

| Selection Agent | Appropriate antibiotic (e.g., Hygromycin) or Herbicide | Maintains selection pressure against escapes during early regeneration stages. |

| Sterile Substrate | Jiffy-7 pellets or Peat:Perlite (3:1) | Provides initial sterile, well-aerated support for plantlets during acclimatization. |

| Anti-Transpirant | Vapor Gard or similar (diluted) | Reduces water loss through stomata during the critical first days of acclimatization. |

This application note details adapted protocols for the production of monoclonal antibodies (mAbs) and vaccine antigens in plant systems, specifically within the broader research context of Agrobacterium-mediated transformation of embryogenic cell suspensions. This approach leverages the scalability, safety, and eukaryotic processing capabilities of plant cells, offering a viable alternative to traditional mammalian and microbial systems for biopharmaceutical development.

Table 1: Comparative Advantages of Plant-Based Production Systems

| Parameter | Mammalian Cells (CHO) | Plant Cell Suspensions | Key Implication |

|---|---|---|---|

| Upstream Cost | High ($500 - $1000 per gram*) | Low ($50 - $200 per gram*) | Significant reduction in production expenses. |

| Time to Biomass | Weeks to months | Days to weeks | Faster turnaround for initial product development. |

| Pathogen Risk | Potential for human pathogens (viruses, prions) | Minimal risk of human pathogens | Enhanced product safety profile. |

| Glycosylation | Complex, human-like | Paucimannosidic; can be humanized via genetic engineering | Requires adaptation for some therapeutics. |

| Scalability | Limited by bioreactor capacity | Highly scalable in contained bioreactors or open fields | Potential for very large-scale production. |

*Estimated cost ranges for production; actual values are product-dependent.

Table 2: Representative Yields of Biologics in Plant Systems

| Target Product | Plant Platform | Reported Yield | Reference Year |

|---|---|---|---|

| Anti-Ebola mAb (6D8) | Nicotiana benthamiana | ~0.5 g/kg fresh leaf weight (FLW) | 2022 |

| SARS-CoV-2 RBD Vaccine Antigen | N. benthamiana | ~1.2 mg/g total soluble protein (TSP) | 2023 |

| Human IgG1 (Model mAb) | Rice Embryogenic Cell Suspension | ~25 µg/g dry weight | 2021 |

Detailed Experimental Protocols

Protocol 1:Agrobacterium-Mediated Transformation of Embryogenic Cell Suspensions for mAb Expression